The Best Pharmaceutical Inventory Management Software

Keep Track of Sensitive Medications and Drugs

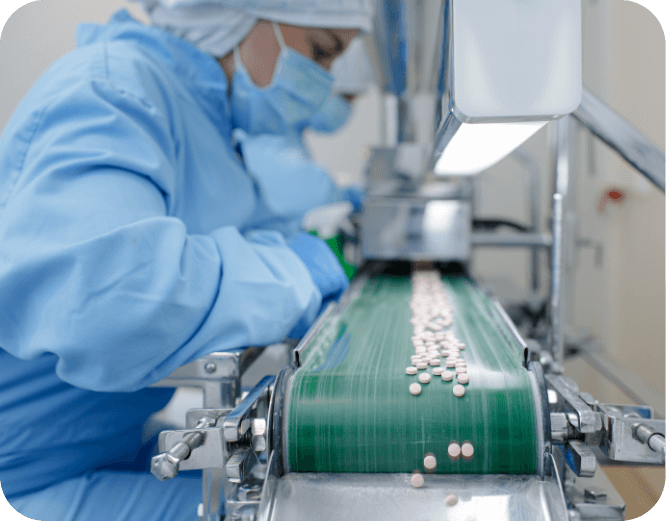

We understand that a big part of pharmaceutical manufacturing includes the complex process of coordinating storage conditions, quality control, and monitoring expiration dates. That’s where we come in.

Our pharmaceutical inventory management software organizes data efficiently and comes with an extensive selection of features to help you keep track of inventory levels, expiration dates, and more! From the supply chain at the manufacturing level to the post-fulfillment batch recall process, our fully configurable pharmaceutical inventory management software has you covered.

What Are Common Pharmaceutical Inventory We Track?

Giving essential stats on all inventory in your manufacturing operations

With so many moving parts in pharmaceutical manufacturing, it is essential to properly manage all materials involved according to their shelf life, expiration dates and storage requirements. Using the right software to help with inventory management is critical to the success of your business or organization.

A few examples of items that our systems can help you manage includes medical supplies, controlled substances, raw materials for drug manufacturing, packaging materials and more. Besides that, our software is also capable of keeping track of your day-to-day consumables, finished goods and returned goods.

The 5 Types of Inventory

Learn about how our system categorizes your inventory items

Whether it’s a large-scale pharmaceutical manufacturing company or a pharmacy, our system helps you efficiently manage inventory. Our pharmaceutical inventory management software categorizes items into 5 inventory types, a comprehensive system designed to handle any type of medical inventory in your facility. Here are some examples of how pharmaceutical and medical inventory would be categorized:

Standard Inventory

This type of inventory item does not need to be tracked by lot, batch, or serial number. This could include items like pipettes, thermometers, beakers, filters, and packaging materials.

Serialized Inventory

Serialized inventory refers to items that have a serial number attached or assigned to it. Some examples include medical devices like EKG machines, or tools used in manufacturing like scales, microscopes, and other lab equipment.

Batch-Lot Inventory

Batch/Lot inventory items often have expiration dates that must be monitored very closely. Some of the finished products of pharmaceutical manufacturing, like vaccines, medications and drugs are considered batch/lot inventory.

Serialized with Quantity

This category refers to inventory with serial numbers attached but are distributed or used in varying quantities. Some items commonly used in pharmaceutical manufacturing include raw materials like raw chemicals, reagents, active ingredients and non-active ingredients.

Non-Inventory Items

Non-inventory items refer to items that aren’t merchandise but are still billable. This includes non-physical items like service fees, software licenses and warranty periods. If you find that some of your inventory management items do not fit it other categories, it would be categorized under this.

How Can We Help Your Pharmaceutical Company?

Learn about how our pharmaceutical inventory management system can help you

Prevent Overstocking & Understocking:

With our inventory system, pharmaceutical companies get maximized visibility into the inventory levels, locations, and movements. This helps your organization manage inventory more efficiently, so you know exactly what’s going on in your warehouses and manufacturing facilities.

Inventory Optimization & Cost Control

By providing real-time visibility into inventory data, our software helps you identify inventory trends, optimize inventory levels, and reduce carrying costs. This means you and your stakeholders can make data-driven decisions to balance inventory while meeting demand and minimizing wasted stock.

Streamlined Order Management

Our pharmaceutical inventory management software helps automate the order management process, including generating purchase orders, order tracking, and order fulfillment. This simplifies interactions with suppliers, reduces manual effort, resulting in improved supply chain performance.

Batch & Lot Traceability

Our Pharmaceutical Inventory System makes it easy to track your finished goods even after they’ve left your facility. This is done by associating batches and lot numbers with inventory items. This ensures accurate tracking throughout the manufacturing process and supports product recalls if needed, making it easy to comply with regulatory requirements.