The #1 Inventory Management Software

What is the best inventory tracking software for efficient inventory management?

Effective inventory management is essential for businesses in any industry. Whether you are a large enterprise managing complex supply chains or a small business looking to streamline your operations, using the right inventory tracking software can make a big difference for your bottom line. We know that every business and industry is different with their own separate challenges and needs, which makes it hard to find an Inventory System that can perfectly fit your business.

We designed our Barcode Inventory System to be fully configurable to work for and adapt to any organization, no matter the industry. Our software helps solve all your organization’s inventory management challenges. Whether it’s creating configurable reports, SKUs, or something else entirely. We will be here to assist you and help your organization stay organized and find success.

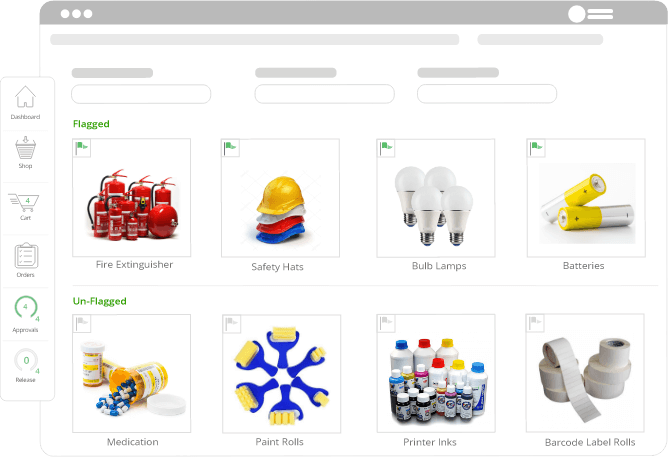

Have You Ever Wanted a Way to Shop for The Inventory in Your Warehouse?

This is why we designed CartCloud

With our latest inventory management mobile app, you can easily browse through all available inventory and place item requests using a digital catalog directly linked to your warehouses, offices, or stockrooms. If you’re working on the go, our mobile inventory tracking app lets you do Inventory Requisitions from anywhere at any time. Whether you’re on a job site or in an office, you can still shop for the items in your facilities. Our app also keeps users informed about their requests through notifications, all the while delivering real-time insights on inventory levels and much more – for multiple locations!

Real-Time Inventory Tracking System for Organizations of Any Size

Basic and advanced inventory management for your business

Our Inventory Software offers a comprehensive range of features suitable for businesses of all sizes, from big global corporations to smaller companies. Our system includes a variety of configurable modules to help you address any unique inventory tracking challenges you may encounter.

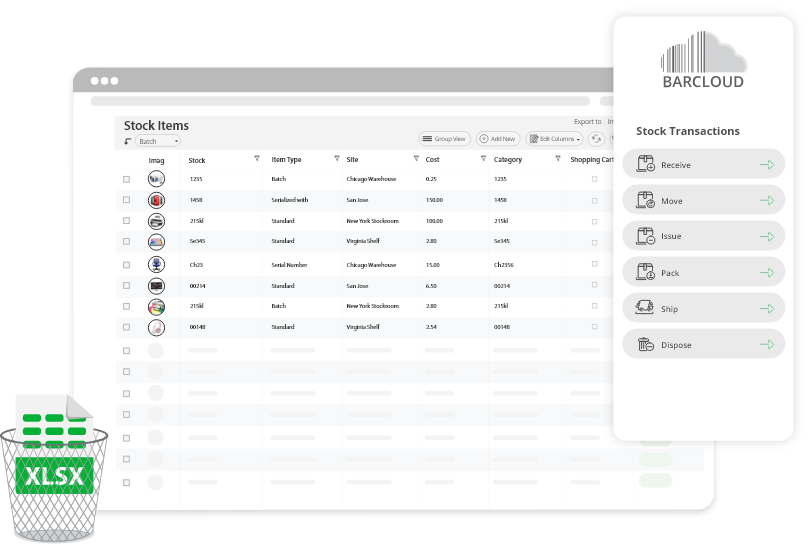

With our Inventory System, you can easily manage day-to-day transactions such as barcoding, receiving, moving, and consuming standard inventory items. Additionally, the system constantly monitors your inventory levels and notifies you when the reorder point is reached.

Explore our Professional, Standard and Lite plans to find what suits you the most!

Need an Inventory Software that is Adaptable?

A flexible inventory system that adapts to your organization’s size and industry

We have been in the inventory tracking industry for decades and are familiar with the unique needs of our customers. With customers coming from a variety of sectors, our experience has helped us understand and address any inventory management need. That has also helped us in designing the best inventory software possible with advanced features that remain user-friendly.

These diverse cases have allowed us to:

- Scale the system and adapt/grow to the ever-changing needs of your organization

- Streamline manual tasks with simplified solutions for optimized workflows

- Create powerful software that will allow you to monitor all your inventory with one system.

Looking for a Customizable Inventory System?

We are the only system that lets you decide the features for your software

Our Inventory Tracking Software puts the power in your hands and comes with comprehensive features for all your needs. You can pick only the features you need, so you’ll never have to pay for a bunch of extra features you will never use. On top of that, once you’ve chosen the features you need, you can configure them to track your inventory your way. With our inventory software, you can easily manage day-to-day transactions, including generating barcodes, receiving, moving, and consuming inventory items.

Base Inventory Tracking Features in Our Inventory Systems

The basic features and tools that you can use within our Inventory Control Systems

Check out some of the tools and features that are included even in our Lite options:

- Import Inventory Data

- Export Inventory Data in preferred formats

- Receive inventory with documented transactions

- Move inventory with documented transactions

- Issue Inventory out to other locations

- Transfer Inventory with configurable fields

- Configurable Inventory reporting options

- Set Min/Max inventory levels alert

- Set general Inventory Alerts that can be sent to you

- Manage Purchase Orders and Sales Orders

- Use our UPC lookup function

- Review Inventory Data Analytics

- Adjust Transactions to include more information

- View Historical Inventory Data and Transactions

- Use our system’s AI generated forecasting

- Create Inventory Picklists

- Note & Flag any inventory items you need

- Manage default Locations

- Pack & Ship Inventory and many more...

Advanced Inventory Management Features

There’s an Inventory System feature for any inventory management need

The list of features that we provide within our Inventory Tracking System is extensive. What sets us apart from anyone else is that we have a feature for anything you could ever need. Of course, you can check our full list of features, but below are just a few of our clients’ favorites:

Inventory Requisition Feature

Anyone with Requisition access can view available stock items, request them, and they will receive them pending a system administrator’s approval.

Purchase/Sales Order Approvals

Set up our system to restrict the receiving or issuing of new Purchase Orders (POs) or Sales Orders (SOs) until they have undergone the approval process that you create.

Min/Max Inventory levels

Set the minimum and maximum level for specific inventory items so you never under or over-stock. You can also set up alerts for when you approach or reach these levels.

Forecasting Inventory Data

Our Inventory Solution looks through your tracking data and gives you a look into trends and projections so you can better plan your organization’s future.

Inventory Kit Assembly/Kitting

Choose inventory items and bundle them together into a SKU (or kits) so you can efficiently manage your orders.

Multi-site Inventory System

One Inventory Management Software System for business operating in more than one independent site.

What are The Benefits of an Inventory Management System?

We are industry leaders for a reason, here are the benefits to our Inventory Software

Efficiency

Using our Inventory Management Software is the best way to keep your processes efficient, your business organized, and your inventory always in sight.

Scalability

Our systems are the only fully configurable Inventory Management Software out there that is flexible enough to grow with your business’ ever-changing needs and requirements.

Automation

Save tons of time and money by automating your process, ditching the excel spreadsheets and paper trails, and eliminating any overstocking/shortage costs due to human error.

Accuracy

Our inventory system can help reduce errors and discrepancies in your inventory counts, leading to more accurate inventory data.

Satisfaction

With accurate inventory data, businesses can ensure they have the products customers want when they want them, leading to higher customer satisfaction and repeat business.

Want to Incorporate AI into Your Inventory Forecasting?

See what the power of Artificial Intelligence can do

Most Inventory Tracking Software have Forecasting Features, but they only use past historical data to create what are essentially trend lines on scatter plots.

We designed our system to give you the option to choose your expansion rate and utilize artificial intelligence technology to create a holistic projection just for you with more accuracy than just using your historical inventory information.

The Most Secure Inventory Tracking System

We know security is important. Here is how we can help:

Having an incredibly secure inventory system is very imperative for any organization. Our inventory system prioritizes maintaining complete confidentiality for your company, vendor, and customer data. With our Inventory Tracking system, you have the flexibility to limit access for specific users, allowing them to only view, access, and use the features that are essential to their role.

Moreover, you can activate our signature capture feature for important transactions. This feature mandates that employees provide a signature before conducting a transaction, resulting in improved accountability and visibility for both employees and inventory items.

Want an Easier Way to Document Inventory Requests?

Learn about our incredibly popular and useful Inventory Requisition Feature

Drawing on our decades of experience, we observed that many organizations waste thousands of dollars on overstocking due to inadequate inventory control. Without an efficient system in place, it can be challenging to maintain quality control, making it easy to overlook or lose track of available inventory.

To address these issues, we have developed the “Inventory Requisitions Feature.” This feature lets you access a comprehensive digital catalog of all available inventory items within your warehouse directly through our Inventory system. You can request specific items you need while others within or outside your organization can also view and place orders if you have given them access to the digital interface.

How To Eliminate Inventory Management Errors

Implement Inventory Tracking Software to reduce the risk of manual data entry

Using traditional manual methods to track inventory like Excel or paper-based inventory tracking methods can be time-consuming and increase the likelihood of human error.

By implementing an Inventory Tracking System, you can effectively manage your inventory and significantly reduce the risk of inaccuracies. Our inventory monitoring application software is highly customizable and offers a wide range of features to help you streamline your inventory management process more effectively than any other solution available.

Inventory Mobile App

Don’t worry about having to purchase hardware to manage your inventory

Users of our inventory tracking software can download and use our Mobile App at no extra charge. Compatible with both iOS and Android devices, our Mobile App makes barcode scanning easy by using your phone’s back camera. You will have unrestricted access to our system, just as you would on a desktop, while utilizing this barcode inventory tracking software. It is also the quickest and most convenient way to scan your items without having to purchase extra hardware.

Benefits of Our Inventory System Mobile App:

- Use your personal devices instead of spending money on hardware.

- Gain full access to the system and perform normal day-to-day transactions.

- Transfer Inventory data from the app to the web for real-time stock visibility and information without dock and sync.

What Are the Different Types of Inventory?

Our system lets you manage Standard, Serial Number, Serialized with Quantity, Batch/Lot, and Non-Inventory

Frequently Asked Questions

How does an inventory tracking system integrate with other business software?

BarCloud’s enterprise inventory tracking solution integrates seamlessly with QuickBooks, ERP, purchasing and CRM systems. These connections reduce duplicate data entry while keeping financial data accurate and streamlining order fulfillment. Integration options can be tailored to your organization’s size and workflow needs.

What industries benefit the most from an inventory tracking system?

BarCloud serves multiple sectors with adaptable tools. Healthcare uses our medical inventory software to manage batch numbers and expiration-sensitive items. Aerospace and Manufacturing track serialized parts to reduce errors. Education monitors IT and lab assets. Government and Military maintain accountability for high-value items. Retail optimizes multi-location stock control to prevent shortages or overstock.

How do inventory tracking systems support regulatory compliance?

BarCloud aids FDA, ISO and industry compliance through batch tracking, expiration monitoring and configurable reports for audit readiness. Approval workflows strengthen accountability and enforce internal controls.

What is the difference between an inventory tracking system and inventory management software?

Tracking systems provide real-time warehouse visibility and item-level accuracy, while management software adds purchasing, analytics and demand forecasting. BarCloud combines both, offering inventory tracking for warehouses and strategic management tools for complete operational control and maximum ROI.