QR Codes in Warehouse Management

How do they help?

Besides barcode technology, our Warehouse Management Systems comes equipped QR codes to help you effectively manage your warehouse inventory. We included QR Codes as you can use this form of unique identifier to store important item information just like barcodes. This tagging system is capable of holding more information than the average barcode, providing you easy comprehensive access to your inventory data.

With QR codes, your staff can easily view warehouse inventory information you stored on each tag when it is scanned. In our systems, you can upload the information onto the code as well as design, modify and print it out.

Easy Access to Inventory Data

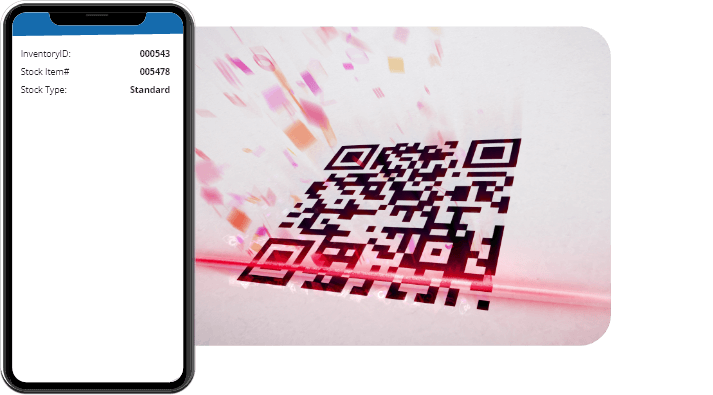

Anyone can easily view QR Code Data with Mobile Devices

To avoid tedious communication back and forth, it’s important that you provide your customers an easy way to get information on your products. A great thing about tagging your items with QR Codes is that people from different organizations or Third-Party Individuals can easily access essential inventory data even without access to our systems.

The QR codes generated from our systems can be scanned with smart devices, instantly giving you access to the information you need in a convenient manner. This streamlines the process of integrating your business operations with third-party warehouses, or other organizations. However, we advise that you only include essential information that you are okay with anyone viewing.

How Do I Choose Between QR vs. Barcodes?

QR Codes

- Stores more information: QR codes are capable of holding more information than barcodes. They can contain up to 7,000 characters.

- Lower Security & Highly Accessible: This tagging system is a little less secure than barcodes. Being easily accessible means that anyone can view embedded information as long as they have access to a smart device.

- More Possible Combinations: By virtue its design being 2D instead of just linear, there are many more QR combinations and designs available to label your warehouse inventory.

- Traditional Manual Data Entry: With QR codes, unfortunately data must be manually entered and updated if there are any updates needed, which means for manual tasks for your employees to juggle.

- Higher Damage Resistance: QR codes can work past a higher threshold of damage meaning they are more durable, perfect for facilities that deal with high volumes of inventory like warehouses or stockrooms.

Barcodes

Learn more about the differences of the two.

- Tighter Security: Barcodes are far more secure than QR Codes with information being less accessible. Only authorized people who have access to our systems are able to view the inventory data embedded in the barcode.

- Stores Less information: Barcodes contain less Information than QR codes do. Standard barcodes can have limits of 128 characters.

- Lower Damage Resistance: Barcodes are more prone to stop working once damaged unlike QR Codes. This means they have a lower damage resistance and are less durable than QR codes.

- Less Possible Combinations: Standard barcodes are linear and 1D, resulting in fewer possible combinations than 2D QR codes.

- More Dynamic: With barcodes, you can eliminate manual data entry as they are linked to a database and automatically update information in the database if there are any changes.

Configuring QR Codes

Design and configure your QR codes’ size, shape, or density.

Just like a standard barcode in our warehouse management software, you can configure your QR codes’ size, shape, or density so they fit on items that are more difficult to tag. This way, you can fit more information on irregularly shaped items as well as smaller or larger items. Something that you can’t do with a traditional barcode.

Easy to Scan and Durable

The benefits of higher damage resistance with QR Codes

With QR codes, you get a higher error tolerance and better durability. This makes them super easy to process and scan. In most cases, QR codes can still be read even if damaged or sitting crooked. This saves you the hassle of constantly reprinting labels the moment they get damaged or stuck on to boxes incorrectly.

For example, if you stick a QR code on a box and it is bent in a weird way and does not lay flat, you will still be able to read the QR code. This ultimately speeds up your warehouse inventory management workflows with less time wasted on correcting errors.

The uses of QR Codes

Learn how our customers used our QR Code feature

Returning Misplaced Items

Misplacing inventory happens more often than we’d like in warehouses and stockrooms dealing with high volumes of product. QR codes provide an easy way to rectify that as you scan simple scan those items and return them to their designated spot based on the embedded information.

Keeping Track of Batch or Lot Inventory

We make it easy to track batch/lot stock items, any necessary recalls, and maintain accountability. When managing items produced in batches like medicine, you can add essential information like the creation date, the batch or lot number, who created it and more.

Labeling Perishable Goods

Tracking perishable inventory is easy with QR Codes. As expiration dates are unlikely to change, this is a good option as it would require less updates to embedded information. When you scan QR code on a perishable good, essential information such as the source of the goods or the expiration date will populate on your device.

Labeling Boxes

With QR codes, you can label boxes and easily identify what items it contains, the quantity of those items, and more. This provides an easy way for you to know exactly what’s inside without opening up the box for inspection.