Defining Your Warehouse Inventory Min/Max Quantities

Efficiently manage inventory levels with our Warehouse Inventory Software

Balancing supply and demand is a delicate and complex process that gets overwhelming very quickly, especially with hundreds of pallets filled with inventory to manage. That’s why we designed our Warehouse Inventory Systems to help address that challenge.

Our Min/Max Quantity feature works together with other features in our systems to help improve your turnover rates and prevent overstocking. The feature analyzes inventory levels, so you always know when your stock levels have dipped past or went over a threshold.

The Min/Max Status Scale

What is the warehouse inventory levels status scale?

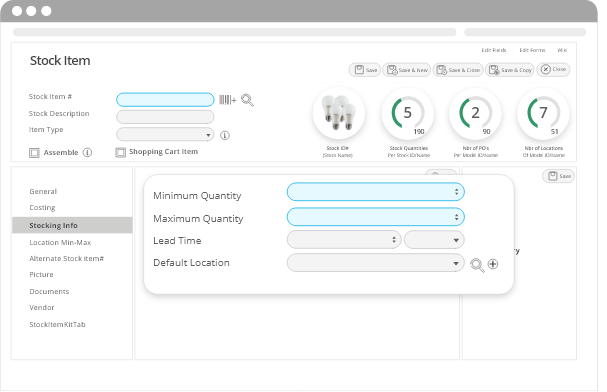

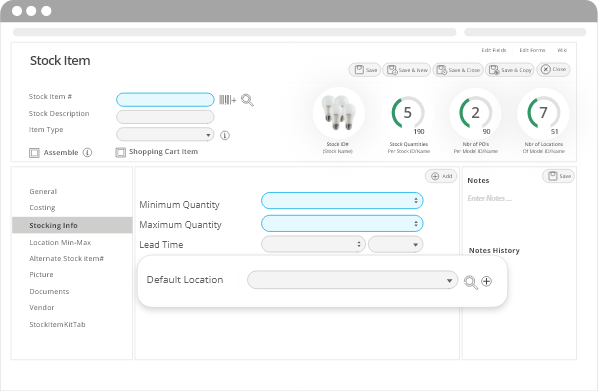

Our Warehouse Inventory System visualizes your inventory levels in a Min/Max Status Scale Panel so you get up to speed at a glance. This scale simplifies inventory data for you and informs you on the available on-hand inventory and real time Quantity On Hand (QOH) numbers.

This is where you can define the exact threshold of inventory quantity that counts as overstocking in your organization. Similarly, you can also set the minimum amount of inventory your warehouse should always have. This can be done for every inventory item in your stockrooms.

Get Alerts through SMS Text or Emails

Learn how our system notifies you on inventory min/max levels

Our systems keeps track of your warehouse inventory levels in real time, constantly updating your database as you and your employees process transactions. Whenever the quantity of an item hits a predetermined threshold, our software automatically generates a text or email alert and sends it to your users. This alert tells you when it is time to restock inventory or pause on receiving more inventory.

These alerts are customizable according to your management needs and can be sent to as many users as deemed necessary. By automating your alerts system, you boost operational efficiency. This is because it cuts down on the confusing traditional back and forth when a person has to manually send out email alerts to everyone involved.

Configurable Reports on Inventory Levels

Improved inventory control with automated reports

We help streamline and improve your inventory tracking workflows with configurable reports. Our systems analyze your inventory data and generate Min/Max Quantity Reports. These reports can be configured to show information on inventory in specific locations in your warehouse. Automate this process and set up a schedule for these reports to be sent to your email. This can be done weekly or monthly.

Setting up Min/Max Alerts Specific to Locations

Learn how to specify Min/Max Inventory Levels for warehouse locations

Our Warehouse Inventory Systems take it a step further and lets you set up minimum and maximum levels for a specific area in your warehouse. This is useful for effective inventory management as you can specify thresholds even for a particular shelf in your stockroom.

You Can Import Existing Min/Max Levels

Learn how to import existing min/max levels data directly into our warehouse management systems.

Your organization may have already determined appropriate minimum and maximum levels for your warehouse inventory. If you have this data prior to purchasing our systems, you don’t have to worry about your work going to waste. Our systems let you import this data, eliminating the headache of manually setting it up for each of your inventory items.

We recommend importing this data in the form of spreadsheets as our software is more compatible with that format. This cuts down on some of the time spent setting up the system so we get you up and running faster.