Enhancing Light Manufacturing Processes

Introduction

Rock Creek Woodworks, situated in Lake Charles, Louisiana, stands as a paragon of excellence in the cabinet design and construction industry, catering to a thriving market from Lafayette to Houston. Their commitment to detail and precision has resulted in exquisite designs and impeccable products. The construction company specializes in light manufacturing and custom cabinetry, constantly engaging with clients to craft plans tailored to their dreams, needs, and budgets. Their custom finishing, featuring an impressive range of premium products, brings a touch of sophistication to the cabinets they produce. With a focus on delivering the best, the company is always looking to improve their operations to provide customers with what they need.

The Challenge of Completing Projects on Time Before Our Inventory System

Prior to using our inventory software, the construction company struggled with properly managing their inventory in their wearehouse. They did not have any pre-existing system to manage their stock, having to manually keep track of their items, including materials and components used to construct cabinets. Their warehouse had to handle inventory like wood, hardware, adhesives and fasteners, finishes, shelving, construction equipment, and more. They often encountered issues with running out of materials during ongoing cabinet assembly projects.

The construction company struggled with visibility and accountability over their items as there was no way to keep track of who took their stock. They also experienced a lot of inconsistencies and disruptions due to natural disasters and the COVID-19 pandemic, often having to pause work and restart again when safe to do so. Without a proper system in place, it was hard to keep track of their inventory and efficiently manage operations at the same time. This made them question what would be the best Inventory System for Construction. And that’s when they found our inventory management software for light manufacturing.

Why Was Our Construction Inventory Tracking Software The Best Fit For Them?

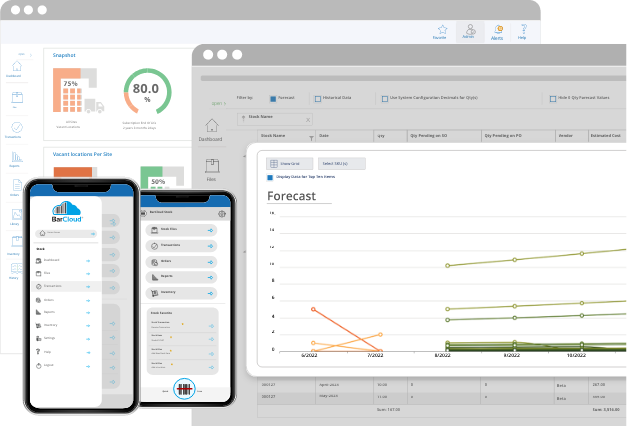

The versatility of our system was a key factor that convinced the construction company to opt for this solution. Our software is fully configurable and scalable, with ability to adapt and grow alongside the business, a perfect solution to help the construction company expand operations in the future. The user-friendly nature of our inventory management software also made it easy for their staff to navigate, making tedious manual tasks a thing of the past. The insights that they could get from our software also provided them a foundation on which they could forecast the amount of materials they would need in advance.

How Does A Inventory Management Software for Construction Companies Work?

Implementing our software was easy, with little-to-no learning curve. Now, the staff at the company use our system on a daily basis, with daily counts of sheet goods to update material usage records. The Issuing and Receiving inventory features were the most-used features for this purpose. These features were integral to their operations, facilitating the tracking and management of materials. As Josh Harris, a representative of the company says, “Lifesaver in our shop.”

With the Reports feature, they were able to use the data collected during daily operations to get a look on the amount of inventory and materials they use for each project. This gave them the opportunity to stock up on the items they would use the most in advance.

The Results

Our inventory management system helped bring greater accountability to the company by eliminating instances of inventory disappearing without a trace. Instead, our software provided them with a comprehensive and dependable paper trail, meticulously documenting every material movement. This approach not only shed light on previously obscure inventory movements but also curbed the losses incurred through unaccounted-for material usage.

With us, they were able to maintain constant control over their stock levels, ensuring that a well-stocked warehouse would be able to consistently supply the necessary materials for each project. This measure directly translated into significant cost savings, as they no longer overspent on duplicate materials or encountered frustrating project delays due to shortages. In essence, our software became an invaluable guardian of their financial resources.

They anticipate that our software will significantly impact their future business objectives by reducing material losses, ultimately paving the way for business growth.

Call-to-Action

To learn more about how you can improve your organization’s efficiency with our Inventory System, check out our website or schedule a demo today at barcloud.com

Read More Case Studies

CASE STUDY

Richland School District 2 – Case Study

With hundreds of valuable assets—including laptops, tablets, and furniture, the district needed a modern system to replace error-prone spreadsheets...

View Case StudyCASE STUDY

Sparrow Academy – Case Study

By implementing our comprehensive tracking software, they streamlined operations, improved accountability for educational resources...

View Case Study

CASE STUDY

Malmstrom Inns & Suites – Case Study

Each property is responsible for safeguarding, tracking, and maintaining government-furnished assets, such as televisions, linens, toiletries, and furnishings...

View Case Study